95%

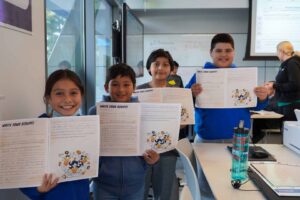

95% of students feel inspired

200+

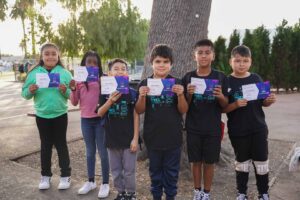

200+ partnerships with schools and industry experts

15+

15+ mobile fabrication labs reaching local communities

ABOUT THE FABLAB

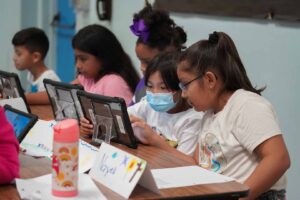

The CSUDH Mobile Fabrication Lab project is at the forefront of innovative STEM education. Our fleet of 5 mobile fabrication laboratories serve K-16 students and teachers, pre-service STEM teachers, CSUDH faculty, and community members. The Fab Lab project brings STEM into classrooms and communities by providing participants with access to fabrication equipment such as 3D printers, laser cutters, vinyl cutters, CNC mills, 3D modeling software, an electronics workbench, and a suite of other tools that will allow anyone to create almost everything. The CSUDH Mobile Fab Labs inspire and create young engineers, inventors, artists, and entrepreneurs!

The on-campus Fabrication Lab, known as the Toyota Center for Innovation in STEM Education, is a state-of-the-art facility equipped with all of the best and latest fabrication equipment. The Fab Lab team along with CSUDH students from various majors work together in the Fab Lab’s active STEM lab classrooms as well as the fabrication space to engage K-16 students in hands-on challenge-based and exciting STEM projects. Rapid prototyping can be a breeze! This stationary Fab Lab encourages collaboration, entrepreneurship, and creativity. It is located on the first floor of the new Science and Innovation building.

FABRICATE TO EDUCATE

CISE and the Fabrication Lab team aim to provide K – 16 students with tangible Science, Technology, Engineering, Art, and Mathematics (STEAM) applications to investigate and solve real-world challenges; instill 21st-century skills through Project-Based Learning (PBL); promote equity within the Southern California region and be a model for sustainable innovation in K-16 STEM education. The Fabrication Laboratories provide students, teachers, and families access to high-tech fabrication equipment, such as 3D printers, laser cutters, vinyl cutters, CNC mills, 3D modeling software, and an electronics lab.

ABOUT CISE

The mission of CISE and its Fabrication Lab project is to bring Science, Technology, Engineering, Art, and Mathematics (STEAM) to the forefront of K-16 education through leadership and service. CISE was created to address issues at the heart of the STEM crisis: the need for qualified science and math teachers; the need to inspire K-16 students through hands-on challenge-based STEAM experiences; the need for more women and minorities to graduate with STEM degrees and pursue careers in the STEM fields.

To fulfill its mission, CISE has developed innovative field-tested programs and services to advance STEAM education in public schools and the community. Core programs include our Fabrication Laboratories, professional development programs for teachers in Next Generation Science Standards (NGSS) and Fabrication Technology, and STEAM Laboratory Schools.

WHY PARTNER WITH US?

In addition to offering authentic STEAM experiences, CISE employs local college students to support instruction. A diverse group of students from CSUDH, and other local colleges, are hired and trained to support learners participating in our STEAM Programs. As STEAM majors, they are committed to sharing their passion for learning and serving as examples for younger students. When you partner with CISE, you allow us to continue to support local college students!